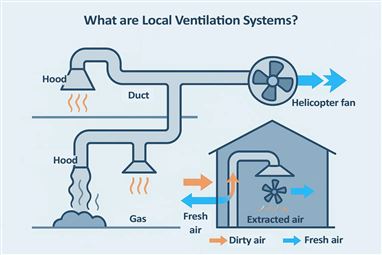

Large-blade industrial ventilation systems designed to maintain optimal air quality and temperature balance in modern livestock facilities and typically mounted on the ceiling are referred to as farm fans. Known in the industry as helicopter fans, these technologies move large volumes of air at low speed (HVLS), keeping stagnant air in constant circulation and minimizing heat stress for animals, thereby ensuring their living comfort.

In enclosed areas where animals are densely housed, the accumulation of harmful gases such as ammonia and increased humidity levels seriously threaten both herd health and productivity. These massive fan systems disperse polluted air near the ground while creating a natural breeze effect over the animals, enabling them to cool down thanks to their wide and gentle airflow. Unlike conventional small-scale ventilation methods, they distribute air evenly throughout the entire space, eliminating dead zones and accelerating floor drying to prevent bacterial growth.

From an operational cost perspective, these systems can climatize very large areas with low energy consumption. For producers who aim to prevent productivity losses in dairy cattle, beef cattle, or poultry farming while protecting animal welfare and increasing profitability, these fans are an indispensable asset. Their quiet operation and long service life enhance overall facility comfort while preventing heat-related diseases and yield reductions, allowing the investment cost to be amortized in a short period.

Key Features That Differentiate Helicopter-Type Farm Fans from Standard Fans

The ventilation requirement in farms is not merely to blow air at a specific point but to efficiently manage the entire air mass within enclosed spaces. While standard industrial fans typically operate at high speed and blow fast, pressurized air into a narrow corridor, HVLS fans known as helicopter-type operate by moving all the air in the environment at low speed through their massive blade structures. The primary engineering objective of these systems is not to create a harsh and noisy wind that disturbs animals, but to generate a soft, continuous, and enveloping airflow felt across every square meter of the facility, naturally mitigating heat stress. Unlike small-diameter fans, this technology focuses not on speed but on the volume of air carried by high torque.

The differences between standard ventilation solutions and next-generation helicopter fans in terms of performance and comfort are as follows:

- Wide Coverage Area: A single helicopter fan can manage the area that dozens of small wall or ceiling fans would affect and leaves no dead zones within the facility.

- Airflow Quality: Traditional fans blow direct and uncomfortable pressurized air onto animals, whereas these large systems create a gentle airflow similar to a natural breeze that reduces stress.

- Energy Efficiency: Since they move a very high volume of air at low speed, the electricity consumption per square meter is significantly lower compared to multiple small fan systems.

- Quiet Operating Principle: While the noise and hum created by high-speed motors can reduce milk yield, HVLS technology operates almost silently, preserving herd psychology.

- Homogeneous Climate Control: By drawing hot air accumulated at the ceiling down to the floor and mixing it, it balances ambient temperature and allows floor moisture to dry more quickly.

This technological distinction is not merely a hardware difference but a strategic choice that directly affects overall business efficiency and profitability. Instead of dealing with the maintenance costs, cleaning requirements, and cable clutter of hundreds of small fans, using a centralized and powerful solution significantly reduces operational burden. Harsh airflows directly hitting animals can trigger respiratory problems or muscle stiffness over time, whereas the circulation created by helicopter fans effectively disperses humidity inside the barn and ammonia gas, protecting animal health and providing a much more comfortable working environment for employees.

The Role of Fans in Eliminating Humidity, Floor Wetness, and Ammonia Odor Inside Barns

High humidity levels in enclosed animal shelters are among the greatest threats that silently damage both the physical integrity of the structure and herd health. Water vapor released into the atmosphere through animal respiration and biological waste remains suspended in the environment when effective air circulation is not provided, creating a heavy and suffocating climate. Helicopter-type fans disperse this dense moisture mass with their continuous and voluminous airflow, replacing it with fresh air and bringing indoor relative humidity down to ideal levels. A drier environment significantly reduces the reproduction rate of bacteria and fungi that cause respiratory infections, acting as a protective shield.

Ammonia gas originating from manure and urine accumulates especially near the floor due to its specific gravity, directly damaging the respiratory systems of lying animals. The removal of this heavy and toxic gas is quite difficult with ordinary ventilation methods because gases tend to stratify in stagnant air. Powerful fan systems break up these toxic gas layers by pushing a wide column of air from the ceiling to the floor, creating continuous mixing and reducing gas concentration to safe limits. Thanks to this clean air cycle, the sharp, throat-burning odor inside the barn disappears, and oxygen intake becomes easier for both animals and workers.

Floor wetness and damp bedding are among the primary causes of costly diseases such as mastitis and hoof rot in cattle farming. The airflow created by fans produces a continuous evaporation effect on floor surfaces, keeping walkways and resting areas dry. A dry floor not only prevents slipping and injuries but also limits the living environment of pathogens, raising the overall hygiene standards of the facility. Bedding materials remaining dry for longer periods reduce operating costs while allowing animals to rest in a clean and comfortable area.

How Is Maximum Cooling Achieved in Large Areas with Low Energy Consumption?

The key to keeping climate control costs under control in facilities with large interior volumes lies in technologies that focus on air volume rather than air speed. Helicopter-type fans, thanks to their specially designed aerodynamic blades, rotate at low speed and push massive air volumes downward in a wide column. This method creates continuous and homogeneous airflow across thousands of square meters using only a small fraction of the electricity that hundreds of small fans would consume. By allocating motor power to moving air volume rather than wind speed, businesses achieve effective circulation reaching even the farthest corners of the facility without straining electricity meters.

This gentle air movement works by lowering the perceived temperature on living beings rather than artificially changing thermometer readings. By accelerating the evaporation of moisture on the skin, it provides natural cooling, offering a comfortable living environment without the need for high-cost, energy-hungry devices such as air conditioners. These engineering marvels, which cover maximum area with minimal energy consumption, amortize their investment cost in a short time while reducing the burden of energy bills and delivering sustainable cooling performance.

The Effects of Proper Air Circulation on Animal Health in Dairy and Beef Farms

The metabolism of high-yield animals raised in enclosed areas continuously generates heat due to production processes, significantly increasing oxygen demand in the environment. Insufficient airflow causes viruses and bacteria to remain suspended in the barn air, facilitating the rapid spread of infectious diseases. A properly designed circulation system constantly renews contaminated air, relieving animals’ respiratory systems and eliminating environmental stress factors that suppress immunity. Clean air is not merely a comfort element but the fundamental cornerstone of sustainable livestock farming.

The direct effects of air quality and circulation on animal physiology are as follows:

- Prevention of Respiratory Infections: It guarantees animals breathe clean oxygen by diluting airborne pathogen density that causes serious lung diseases such as pneumonia.

- Reduction of Mastitis Risk: By keeping bedding and stalls dry, it eliminates breeding environments for bacterial udder infections, the biggest enemy of dairy cows.

- Feed Intake and Metabolism: By preventing heat stress, it avoids appetite loss and prevents metabolic diseases associated with reduced dry matter intake.

- Fertility and Reproductive Performance: It counteracts the suppressive effect of high body temperature on reproductive hormones, increasing insemination success and maintaining pregnancy rates.

- Hoof and Foot Health: By ensuring floors dry quickly through continuous airflow, it minimizes hoof rot and lameness problems caused by wet conditions.

Healthy herd management requires focusing on preventive veterinary measures rather than treating diseases after they occur. Effective ventilation systems that reduce veterinary expenses and antibiotic usage are not merely a temporary relief but a vital investment that extends the economic lifespan of animals. Animals that live stress-free, breathe clean air, and are housed in hygienic environments fully reflect their genetic potential in the field, directly contributing to business profitability.

Leave a Comment