Industrial helicopter fan investments require first clarifying the difference between your current climate control expenses and the low energy consumption of next-generation HVLS technology in order to calculate return on investment (ROI). By dividing the total purchase and installation cost by the monthly energy savings together with the financial gains arising from increased animal welfare or personnel productivity, you can easily determine how long it will take for the investment to pay for itself. Especially in large livestock barns or high-volume warehouses, this calculation should not only include reduced electricity bills but also increases in milk yield, reduced veterinary expenses due to lower heat stress, or preserved product quality thanks to humidity control.

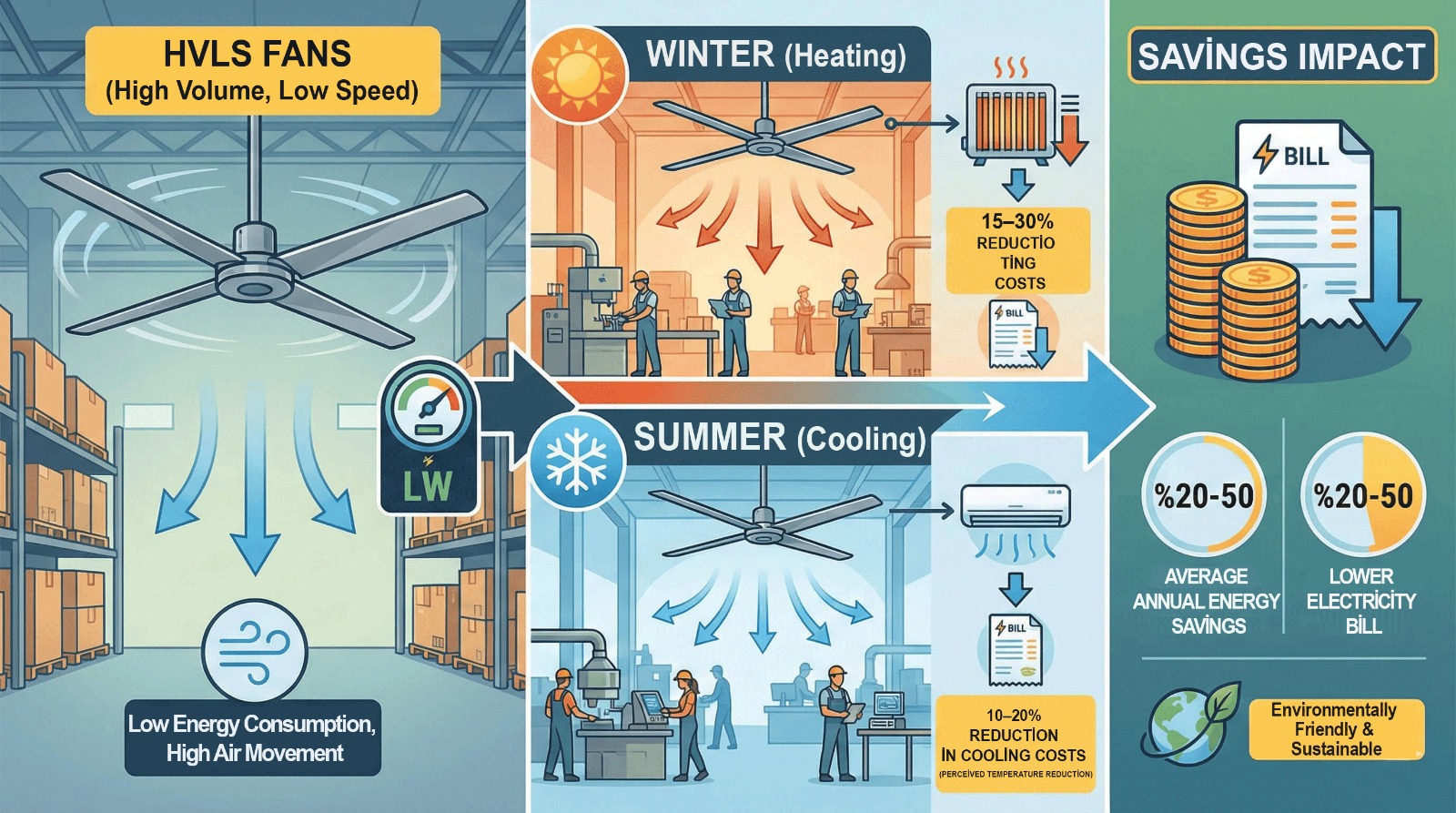

These massive systems used in large square-meter areas and high-ceiling structures, unlike high-speed standard fans, physically reorganize the thermal balance of the environment by moving huge volumes of air at low speed. By bringing the heated air accumulated at the ceiling down to floor level and mixing it homogeneously with the cooler air in the space, this technology significantly reduces heating costs in winter while noticeably lowering the perceived temperature in summer. For business owners, this mechanical advantage means that existing heating and cooling systems operate far less, resulting in permanent reductions in operational expenses, which are reflected as positive values in the profitability statement every month.

In financial payback analysis, it is critical to account for the invisible savings provided by ease of maintenance and operation, because a single helicopter fan can manage the airflow created by dozens of small industrial fans much more quietly and efficiently on its own. Fewer motors, simpler cabling infrastructure, and a long service life minimize failure risks, easing the technical maintenance burden on the business and preventing unexpected expenses. In barns and farms, reduced disease risks thanks to dry floors and continuous clean air circulation prove that the investment is not limited to energy savings alone, but also creates a long-term source of profit by protecting production continuity and the health of living assets.

How Much Can You Actually Save on Your Electricity Bill?

Unlike traditional high-speed fans, HVLS technology uses motor power not to cut through the air rapidly but to gently move a large mass of air. This operating principle enables the creation of homogeneous and effective air circulation in vast areas with far less energy than that consumed by a standard industrial fan. The ability of a single helicopter fan to deliver the cooling effect of dozens of small fans with much lower amperage values translates directly into a significant reduction in operating expenses at the end of the month.

The most tangible gains in energy costs emerge in scenarios where the system operates in integration with existing heating and cooling equipment. In summer, the wide blades that noticeably reduce perceived temperature ease the workload of cooling units, allowing thermostats to be set at more economical levels. In winter, by bringing the warm air trapped near the ceiling down to the floor in accordance with the laws of physics, heaters are activated far less frequently, resulting in a substantial increase in energy efficiency related to climate control.

When costs per kilowatt-hour are analyzed, it becomes evident that these systems offset their initial installation costs in a surprisingly short time. Especially in barns, shelters, and large-volume facilities operating 24/7, motor efficiency and low friction losses slow the movement of the electricity meter. While optimizing your business’s energy budget, considering not only the immediate bill but also the cumulative gains achieved through long equipment life and low power consumption is the most accurate approach for financial sustainability.

Hidden Revenues from Milk Yield and Animal Health

When establishing the profitability equation in farm management, the focus is often solely on energy expenses, yet the biggest leakage is hidden in production efficiency. High temperatures and insufficient airflow create serious thermal stress on animals, causing their metabolism to expend energy merely on lowering body temperature. This means that energy that should be allocated to milk production is diverted to survival efforts, leading to a silent erosion of revenue that should enter the business’s coffers. Proper climate control investment expands the animal’s comfort zone, enabling its genetic potential to be fully realized in the field.

The positive impacts of these hidden revenue items on the business budget can be summarized under the following concrete headings:

- Stability in Milk Yield: While milk production drops dramatically in heat-stressed cows, production levels are maintained in animals kept at ideal coolness, turning summer losses into gains.

- Fertility and Reproductive Success: High body temperatures negatively affect reproductive performance; when a cool environment is provided, pregnancy rates increase and insemination costs decrease.

- Feed Efficiency: Animals lose appetite in hot environments, reducing dry matter intake; cooled animals consume feed more willingly, increasing their capacity to convert feed into milk.

- Reduction in Veterinary and Medication Costs: Continuous air circulation keeps floors dry, slowing bacterial growth and preventing costly issues such as mastitis and hoof diseases.

Healthy herd management perhaps creates the most critical multiplier effect when calculating the financial payback period of a technical investment. Thanks to dry bedding areas and clean air, reduced disease risks provide significant relief in medication and treatment budgets. Therefore, expenditures on these systems should be evaluated not merely as hardware costs, but as strategic moves that secure the biological performance of the herd and the production capacity of the business.

Operating Cost Comparison Between Standard Industrial Fans and HVLS Fans

Many facility managers believe that using numerous high-speed small fans is a good idea for cooling large spaces, but this approach results in inflated energy bills at the end of the month. Standard industrial fans create fast airflow within narrow corridors, whereas HVLS technology generates slow yet effective air movement covering the entire volume with its massive blades. The fundamental difference lies in the number of motors required to condition the same square footage and the total power these motors draw from the grid; in other words, the issue is not merely blowing air, but managing it at the lowest possible cost.

The operational differences between the two systems and their impact on your budget can be clarified through the following points:

- Energy Consumption Balance: Standard fans operate at high speeds, continuously consuming maximum power, whereas HVLS systems rotate at low speeds, moving large masses with far less energy and sparing the electricity meter.

- Hardware and Infrastructure Load: While cooling a large warehouse with dozens of small fans requires extensive cabling for each unit, a single large fan eliminates complex electrical infrastructure, panel costs, and cable clutter.

- Maintenance Intervals and Failure Risk: As the number of motors in operation increases, so do the likelihood of failures and maintenance burden; using fewer but higher-quality components minimizes service costs and part replacement expenses.

- Noise Pollution and Comfort: Mechanical noise generated by high-speed blades disrupts employee concentration and animal comfort, whereas quietly operating large blades perform their task unobtrusively in the background.

At the initial purchase stage, the unit price of standard fans may appear attractive, but when operational costs over time are examined, the balance quickly shifts. The cumulative electricity consumption and frequent maintenance needs of high-speed fans create a continuous expense item in the operating budget, whereas next-generation wide-blade systems amortize quickly and move into profitability. Therefore, making the choice based not on the price tag alone but on the total cost throughout the equipment’s economic lifespan is the most rational commercial decision.

How to Calculate Return on Investment and Energy Gains Step by Step?

To clearly define the payback period of an investment, available data must be translated into a concrete mathematical equation. This process requires a holistic analysis that includes not only the fan’s price tag but also the business’s current energy unit costs, daily operating hours, and the annual load of the climate control system. To perform an accurate calculation, you should first compare the total consumption of existing cooling or ventilation equipment with the estimated consumption data of the new system, revealing the difference on an annual basis.

The basic calculation steps to follow when creating your financial table are as follows:

- Current Consumption Analysis: Determine the net expense reflected in the monthly bill by summing the hourly energy consumption of all operating fans and supporting cooling units.

- New System Consumption: Calculate the electricity that the installed helicopter fans will consume over the same operating period based on their technical power ratings, and subtract this from the current expense.

- Climate Control Support: Estimate how much less frequently air conditioners and heaters will operate thanks to the fans distributing heat in winter or cooling in summer, and add the resulting fuel savings to the total.

- Maintenance and Operational Expenses: Add up the annual costs of periodic part replacements, lubrication, and breakdowns for the old system, and include the advantages offered by the low-maintenance new technology.

- Amortization Period: Divide the total monthly gain obtained by the purchase and installation cost of the fan to determine how many months it will take for the investment to become profitable.

The table that emerges from this mathematical process enables you to base investment decisions on concrete data rather than intuition. Typically, calculations made on paper result in payback periods that are significantly shorter when combined with on-site efficiency gains, animal welfare improvements, and employee satisfaction—benefits with indirect financial value. Speaking the language of numbers protects the operating budget while simultaneously providing a long-term guarantee for modernization efforts.

The Hidden Cost of Choosing the Wrong Fan for Your Business

When a ventilation system unsuitable for the volume and architectural characteristics of a space is chosen, business owners often focus on the lower initial investment cost, but the real burden is paid during operations. Fans with insufficient capacity or improper placement must operate continuously at their limits to achieve the desired air circulation, rapidly depleting motor lifespan while uncontrollably increasing energy consumption. Failure to achieve the expected cooling effect disrupts humidity balance, reducing employee performance and causing animals in areas such as barns to experience thermal stress. High electricity bills paid every month and depreciation losses caused by equipment operating constantly under maximum load gradually transform the cost of this wrong choice into massive damage.

Technical incompatibility is not limited to energy waste; it also deeply affects the facility’s overall maintenance budget and production quality. Weak systems that struggle to exhaust polluted air facilitate corrosion of metal components and keep floors persistently damp, shortening building lifespan. Moreover, when fans expected to ease heating and cooling loads fail to perform, existing air conditioners and heaters work harder to compensate, accelerating wear across the entire climate control infrastructure. Ultimately, the budget initially perceived as saved is extracted from the business’s coffers through unplanned service interventions, part replacements, and production losses.

Leave a Comment