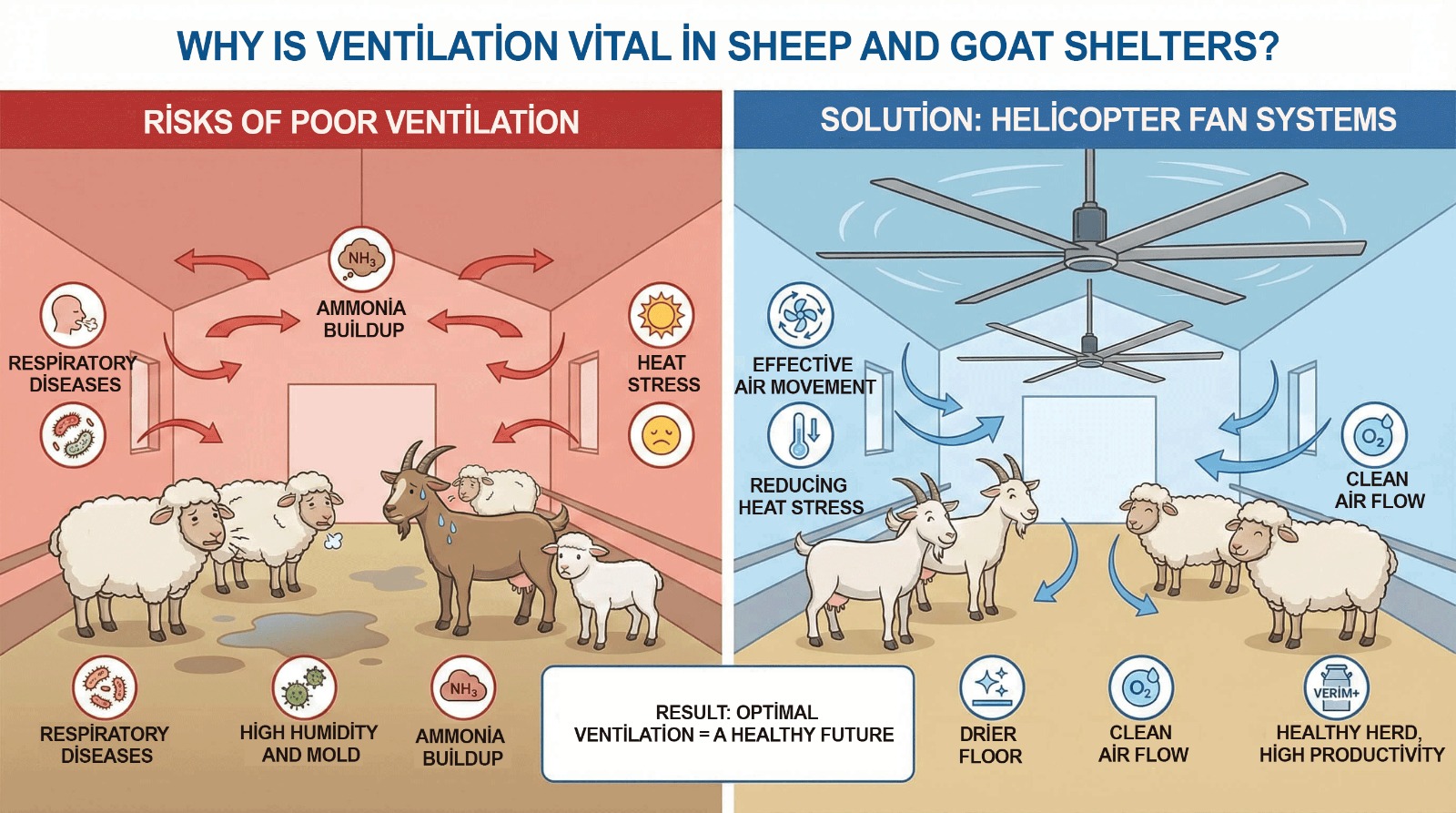

One of the most fundamental factors that directly determines productivity in sheep and goat farming is the management of air quality inside the shelter. Especially to prevent animals from entering heat stress and to exhaust the polluted air indoors, the most effective solution is wide-blade-span helicopter fan systems. These systems send a strong yet gentle airflow toward the ground, providing even cooling at every point in the shelter and helping protect animals from respiratory diseases.

This high-volume, low-speed fan technology controls a much larger area compared to traditional ventilation methods. By supporting the rapid drying of moisture on the ground, it significantly reduces ammonia gas buildup and bacterial formation. When animals’ thermal comfort is ensured, their metabolism focuses on meat and milk production rather than balancing body temperature, which visibly improves the overall performance of the operation.

From an energy-efficiency perspective, helicopter-type fans create maximum air circulation with low electricity consumption, reducing operating costs. Thanks to their quiet operating principle, they do not cause noise-induced stress in animals and preserve herd calm. In modern small ruminant facilities, installing these systems is not just about instant cooling; it is the key to creating a sustainable and healthy rearing environment in all four seasons.

The delicate lung structure of small ruminants can be seriously affected even by the slightest deterioration in air quality in enclosed environments. Moisture accumulated inside the shelter and manure-related gases directly damage animals’ respiratory tracts, opening the door to hard-to-reverse diseases. Not only eliminating bad odors but also keeping oxygen levels continuously fresh is not a preference—it is a necessity for maintaining a strong immune system in the herd. When fresh airflow is not provided, animals expend extra energy to regulate their body temperature, which directly causes sharp declines in meat or milk yield.

A properly planned ventilation system prevents the following critical problems in the operation:

- Minimizing respiratory infections, especially pneumonia cases.

- Rapidly removing toxic ammonia gas from the environment caused by urine and manure accumulating on the ground.

- Keeping bedding areas dry to prevent the growth of bacteria and parasites.

- Preventing heat stress during hot periods and the sudden deaths associated with it.

- Increasing feed utilization rates by keeping animals calmer.

For healthy herd management, environmental climate control is as decisive a factor as ration quality. Insufficient air circulation is like an invisible wall that halts animal development and seriously undermines profitability. Overcoming this barrier and achieving sustainable production is only possible by installing professional systems that exhaust the dirty, humid, heavy air inside and replace it with fresh air. Animals provided with an airy and spacious living area fully exhibit their genetic potential and return it to the producer as high performance.

How Can Heat Stress and the Ammonia Problem Be Solved in Small Ruminant Farming?

In hot weather, the moment animals reduce feed intake and start seeking shade is the first sign that productivity loss has begun. However, the real danger is the acceleration of manure fermentation as temperatures rise and the ammonia level in the environment exceeding the critical threshold. This invisible toxic gas clings to animals’ lungs, reducing respiratory capacity, while heat stress also weakens body resistance. This dual threat creates a vicious cycle that silently erodes herd health and makes economic losses inevitable.

Solving the problem at its root starts with properly managing airflow circulation inside the shelter. A strong and continuous airflow reaching the ground keeps bedding areas dry, effectively drying out the source of ammonia release. In an environment without wetness and humidity, bacterial growth stops and foul odors are prevented at the source. The same air movement lowers the perceived temperature through the wind-chill effect it creates on the animals, easing their metabolism and encouraging them to return to feeding.

Using high-volume, low-speed fan technologies completely transforms the barn climate by exhausting polluted air while distributing fresh oxygen inside. As stagnant air begins to move, heavy gases that settle near the floor disperse, creating a spacious living environment for the animals. Animals free from stress, with lungs filled with clean air, can convert their genetic potential into production. This climate-control move is not just a seasonal measure; it is the strongest insurance for a sustainable and profitable livestock operation.

What Kind of Airflow Do Helicopter Fan Systems Provide in Barns?

With their wide blade structure, these systems capture the large air mass accumulated at the ceiling and push it toward the ground in a massive column. Unlike the narrow, sharp wind created by standard propellers, this technology delivers a voluminous and soft downwash that covers the entire area. This block of air descending from above disperses the stagnant and polluted atmosphere at animal level and instantly increases the oxygen level in the environment.

When the airflow reaches the ground, it does not stop there; it spreads horizontally in all directions along the floor surface. This horizontal movement reaches even the most secluded corners of the barn, drying moisture and wetness in bedding areas. This sweeping effect on the ground prevents the accumulation of heavy gases such as ammonia, curbs bacterial formation, and maximizes hygiene standards.

The continuous airflow passing over the animals removes the heat layer on the skin surface, lowering the perceived temperature. Without creating an uncomfortable storm-like impact, it works like a natural breeze, refreshing the animals. Thanks to this sensitive cooling method, animals focus on productivity gains instead of spending energy trying to cool themselves.

The horizontally moving air rises upward again when it reaches walls or obstacles, forming a perfect circulation loop inside the shelter. Through this circulation, hot and cool air layers mix, providing an even climate at every point in the environment. Homogeneous temperature and clean air distribution is achieved throughout the space, preventing the formation of polluted air pockets anywhere.

The Role of Proper Ventilation in Increasing Milk and Meat Yield

No matter how high the animals’ genetic potential is, it can never fully translate into productivity unless environmental conditions support it. Dirty and stifling air shifts metabolism into defense mode, causing animals to restrict feed intake due to survival instinct. When a cool, oxygen-rich environment is provided, animals do not have to expend extra effort to regulate body temperature and can allocate all consumed energy to production activities. Proper climate control is a critical mechanism that prevents expensive rations from being “spent” on body heat and ensures feed turns directly into profitability.

Especially in lactating herds, maintaining continuous thermal comfort is the surest way to prevent sudden drops in milk volume and quality losses in fat ratio. In fattening groups, fresh air circulation maximizes feed conversion and noticeably accelerates daily live-weight gain. A herd free from stress, without respiratory issues, and with a strong appetite returns to the owner as high-tonnage production and a high-quality end product. A well-planned ventilation infrastructure is not a luxury; it is a strategic production tool that protects production volume.

Classic Fans or Helicopter Fans: Which Is More Advantageous?

High-speed standard industrial propellers push air at very high speed through a narrow tunnel, affecting only a limited area. This operating principle can cause animals standing right in front of the device to be exposed to excessive wind and become stressed, while other animals just a few meters away may not benefit from the cooling at all. In contrast, modern wide-blade systems dominate the entire space by moving air slowly as a large mass instead of piercing through it. Covering every corner without leaving blind spots, this technology provides a uniform climate-control standard across the entire facility rather than only a specific corridor.

In terms of animal welfare and environmental hygiene, harsh and noisy classic devices can stir up dust from the ground through the turbulence they create, triggering respiratory diseases. New-generation technologies that rotate quietly at low speed, on the other hand, cool the herd without startling it by creating a natural-breeze sensation and help drive away pests such as flies. Thanks to their ability to dry ground moisture evenly, they also simplify manure management and prevent ammonia gas accumulation with far superior performance compared to traditional methods.

On the scale of energy efficiency and long-term costs, the advantage clearly lies with modern systems. The total electricity consumed by dozens of small fans required to effectively cool the same square footage is many times higher than the consumption of a single large-volume fan. Eliminating cabling complexity, maintenance burden, and noise pollution, this solution quickly recovers its investment cost through high energy savings. For operators, this choice is not merely a momentary ventilation fix, but a strategic fixed-asset investment that increases profitability.

Leave a Comment