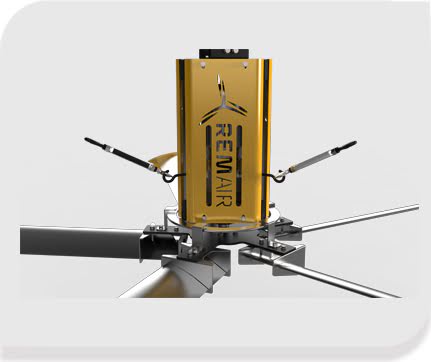

Long-life fans with seamless load bearing mechanismPower, as a result of the extra bearing functiondoes not create an extra axial load on the transmission mechanism and provides a long lasting system. Inside the bearing Axis misalignment is prevented by the design with triangular bearings. |

|

|

Powerful systems with specially designed gearboxHelicopter fans are high torque systems.In this case, the power transmission mechanisms are very prone to breakage. Monoblock Gearboxes used in REMAir fans, It is specially produced by Remak Redüktör for fans and contains durable and strong gears. |

Aerodynamic wing technologyRight-angled blades fan for high air circulationplays a big role in their systems. REMAir fans inside the wings used are specially made of aluminum “Aerodynamic” produced with equations, and the angular settings and maximum provides air displacement. |

|

|

Air Flowing Body DesignIn cases where there is air flow, the surfaces that the air comes into contact with should not encounter an obstacle where it comes into contact within the scope of fluid mechanics. REMAir fans are unique in the R&D processA triangular design is preferred for maximum air flow without compromising on design. |

Secure ropes with safe assembly and designHelicopter fans can pose a risk in uncontrolled use given their large blade spacing and weight. Like thisIn REMAir, in order to prevent such situations, the main body Securing the wings together with the steel cables holding them for the safety of the patient's health and safety. |

|

|

Design that prevents irregular air with special flaps(The yellow part of the wing and the wing tip will be used. We do not use the whole wing.) At high speeds, wings tend to create “turbulence” in the working environment due to their cross-sectional profile. In other words, they cause uneven distribution of the air. Thanks to the plastic flaps in REMAir fans, turbulence is minimized, as in airplanes. |

Why REMAIR?

- Provides quiet operation (maximum 51 db) at high power.

- Provides comfortable and economical air conditioning in summer and winter.

- Cooling the environment with air flow from the ceiling increases the productivity and comfort of workers and animals.

- Fan speed can be adjusted manually thanks to the reducer. It has a cooling system with speed adjustment (inverter) and suitable for automation.

- Reduces the humidity on the floor and in the environment and protects the machines, goods and materials in the environment from humidity.

- It helps to remove hot and dirty air and bad odors.

- It offers environmentally friendly, economical solutions.

- It is much more economical in terms of cost, application and maintenance compared to existing cooling systems.

- Quickly dries wet floors with its specially designed wing structure.

- Provides up to 15% increase in meat and milk production.

- Completely dries manure in summer and winter in open and closed fattening areas.

-

980

By Year

CUSTOM PRODUCTION

Capacity -

28430

By Year

SPARE PART

Capacity -

2800

By Year

FAN REDUCER

PRODUCTION Capacity -

38

Exports Countries