Providing effective ventilation in factory environments is critical to protecting employee health and increasing production efficiency. Among the most suitable ventilation fans for factories, one of the standout options is helicopter-type HVLS fans. These fans operate at low speed, deliver high-volume air circulation, and create homogeneous air distribution across large areas. They offer significant advantages over traditional solutions in terms of both energy efficiency and ambient comfort.

HVLS helicopter fans provide ideal solutions, especially in high-ceiling production areas. By distributing air evenly from top to bottom, they eliminate temperature differences, providing cooling in summer and heat recovery in winter. Compared to commonly used axial, radial, centrifugal, or cabinet fans in factories, they consume less energy and operate more quietly. In this way, they not only enhance worker comfort but also reduce the carbon footprint, offering an environmentally friendly approach.

When choosing a fan, factors such as the size of the production area, indoor temperature, humidity level, and equipment layout must be considered. Helicopter HVLS fans provide flexibility in adapting to these variables. In environments with heavy dust, smoke, or chemical emissions, they can be integrated with supporting exhaust systems to create a complete ventilation solution. In addition, their long lifespan and low maintenance needs minimize operating costs.

Creating the most suitable ventilation system for a factory is not limited to choosing the right type of fan. A detailed needs analysis should be conducted before implementation, fan placement should be carefully planned, and energy efficiency must be taken into account. Helicopter HVLS fans are a strong solution that meets both technological and environmental expectations in modern production facilities.

Which Fan Types Should Be Preferred in Factory Ventilation?

The type of fan to be preferred in factory ventilation depends on many variables such as the size of the production area, indoor temperature, humidity level, machinery, and chemicals used. In high-ceiling, large-volume spaces, effective air circulation is required. At this point, helicopter-type HVLS fans, which provide high-volume airflow at low speed, come to the forefront. However, in some production lines, more intense pressure and targeted airflow may be required. In such cases, using different fan systems together yields more efficient results.

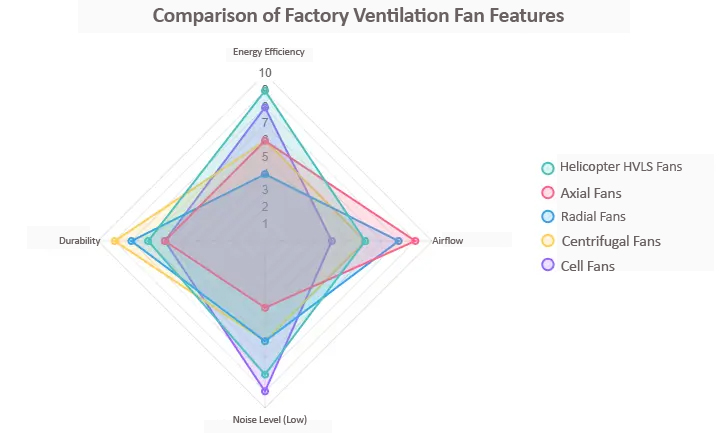

The most commonly preferred fan types in factory ventilation:

- Helicopter HVLS Fans: Provide homogeneous air distribution in large areas with low energy consumption

- Axial Fans: Offer high-flow solutions in areas requiring rapid air movement

- Radial Fans: Effective in production lines that require high-pressure airflow

- Centrifugal Fans: Stand out with durability in dusty and particle-dense environments

- Cabinet Fans: Suitable for sensitive production areas with noise control and filtration features

Choosing the right fan not only ensures air exchange but also balances indoor temperature, increases worker comfort, and reduces energy costs. Therefore, when planning a ventilation system, the entire system should be evaluated holistically rather than being limited to a single fan type. Since each factory has its own unique structure, fan selection should always be supported by site-specific needs analyses.

What Are the Differences Between Axial and Radial Fans?

Axial and radial fans differ in terms of airflow direction and application purposes. Axial fans move air parallel to the fan shaft. These fans are used in wide areas that require high airflow and usually operate at low pressure. They are ideal for circulating air quickly in open areas, tunnels, or large-volume facilities. Thanks to their compact structure, they save space and stand out with energy efficiency.

Radial fans, on the other hand, move air radially from the center outward. Since they provide high-pressure airflow, they are preferred in narrower, ducted, and resistant environments. They work more stably in dusty, particle-filled, or filter-requiring conditions. They may be quieter than axial fans and provide advantages where noise control is necessary. Although their application area is narrower, they deliver very strong performance where needed.

How Is Air Circulation Achieved in Large Areas with HVLS Fans?

HVLS fans provide effective circulation in large areas by creating high-volume air movement at low speed. The wide blades of the fan evenly distribute air layers from ceiling to floor. This prevents hot air from accumulating at the top and creates a homogeneous temperature balance in the space. Since both horizontal and vertical airflow are balanced, the need for cooling or heating systems decreases. This provides energy savings while enhancing indoor comfort.

Fans are generally preferred in production facilities, warehouses, sports halls, and livestock buildings with high ceilings and large volumes. These systems prevent air accumulation or stagnation in large areas while also supporting humidity control. Continuous air movement not only creates a healthy indoor environment but also reduces the risk of product spoilage. HVLS fans are a powerful solution that meet long-term performance and comfort expectations with controlled airflow.

Industrial Advantages of Centrifugal Fans

The industrial advantages of centrifugal fans stand out with their ability to deliver high performance even under challenging conditions. Thanks to their robust structure, these fans are reliably used in the evacuation of heavy dust, smoke, steam, and chemically contaminated air. Their special design that directs airflow from the center outward ensures efficient operation even at high pressure. Especially in confined spaces and environments with intensive duct systems, centrifugal fans provide durable and efficient solutions.

Advantages of centrifugal fans in industrial applications:

- Operate with enough power to meet high-pressure air demands

- Quickly evacuate dust, smoke, and harmful gases

- Compact design suitable for use in confined spaces

- Durable body suitable for long-term use

- Easy integration with duct systems

- Quiet operation reduces noise pollution

- Can be manufactured with chemically resistant materials

Centrifugal fans are especially preferred in industries where ventilation plays a critical role, such as metalworking, paint shops, plastics production, and food processing. With advantages such as high efficiency, safe exhaust, and system compatibility, they ensure workplace safety while supporting sustainable production processes. A properly designed centrifugal fan system is a long-term and economical investment.

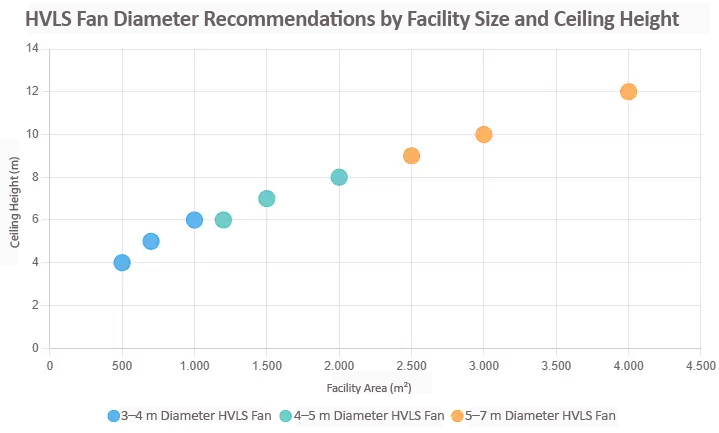

How Should Facility Size and Ceiling Height Be Considered in Fan Selection?

Facility size and ceiling height are key factors in ensuring proper air circulation when selecting fans. Low-capacity fans are insufficient in large-volume, high-ceiling spaces and cause air to stagnate in certain areas. This leads to temperature differences, moisture buildup, and reduced worker comfort. In such facilities, high-capacity fans with wide coverage areas should be preferred. HVLS fans, in particular, provide efficient performance in such areas by delivering balanced airflow over a large surface.

In smaller facilities or those with limited ceiling height, different fan types become more suitable. Axial or radial fans can be more effective in confined spaces by providing targeted airflow. In such areas, not only airflow capacity but also direction, installation point, and vibration control matter. A fan chosen based on the structural characteristics of the facility ensures energy savings and contributes to efficient system operation by creating uniform airflow.

The success of a fan system depends not only on capacity but also on proper placement and the choice of a fan type suitable for the environment. The larger the facility and the higher the ceiling, the greater the temperature differences between air layers. Preventing these differences is critical for both product protection and occupational safety. Therefore, when choosing a fan, decisions should be based not only on brand or model but also on the facility’s physical parameters.

Which Is the Most Efficient Fan Model?

The most efficient fan model is helicopter HVLS fans, which deliver high performance with low energy consumption in large spaces. Thanks to their large-diameter blades, these fans move air slowly but powerfully and create uniform airflow from ceiling to floor. Particularly in high-ceiling production areas, warehouses, and sports halls, they reduce the load on HVAC systems. Thus, they provide both energy savings and improved comfort.

Helicopter HVLS fans operate at much lower speeds than classic fan models while achieving effective results across wide surfaces. With quiet operation, low maintenance needs, and long-lasting structure, they offer a sustainable solution. They create a cooling effect in summer and push warm air downward in winter, balancing indoor temperatures. In this respect, they offer not only energy efficiency but also a strong advantage in improving indoor air quality. They are both an eco-friendly and economical choice for businesses.

Leave a Comment