Air circulation in warehouses and logistics centers plays a critical role in both employee health and product safety. Inadequate air circulation can cause the accumulation of harmful gases and dust particles, negatively affecting workers’ respiratory systems. In addition, imbalances in temperature and humidity can lead to the deterioration of sensitive products. Therefore, an effective air circulation system both enhances workplace safety and preserves product quality.

A well-planned air circulation system balances the temperature and humidity levels inside the warehouse, increasing energy efficiency. This allows heating and cooling systems to run less frequently, reducing energy costs. Furthermore, regular airflow prevents the formation of hot air pockets, making the temperature distribution inside the warehouse more uniform. This both improves employee comfort and optimizes energy consumption.

Overlooking air circulation in warehouse design can lead to serious long-term problems. For example, insufficient air circulation can cause moisture build-up and mold growth, damaging both products and building structures. Moreover, poor air quality can reduce employee productivity and cause health issues. Therefore, an effective air circulation system in warehouses and logistics centers is indispensable for operational efficiency and sustainability.

Why Does Air Circulation Play a Critical Role in Warehouses?

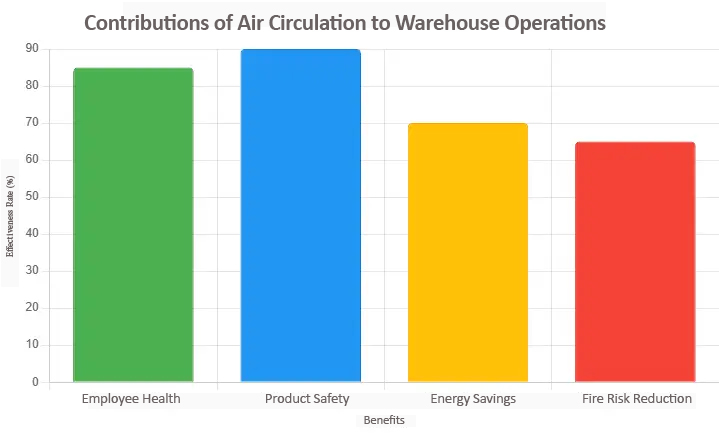

Air circulation in warehouses is a factor that directly affects many processes, from employee health to product safety. In enclosed, large-volume spaces, failure to expel polluted air gradually reduces oxygen levels and leads to the build-up of harmful particles. This both decreases employee performance and can increase risks such as fire and explosion. In addition, if temperature differences are not balanced, the shelf life of sensitive products is shortened and energy consumption increases. Air circulation is not merely a comfort feature; it is the foundation of efficient and safe warehouse management.

Main Reasons Why Air Circulation Is Critical in Warehouses:

- Protects employee health by ensuring continuous renewal of indoor air

- Balances heat distribution to deliver energy savings

- Controls humidity to prevent product spoilage

- Reduces fire risk and prevents the accumulation of harmful gases such as carbon monoxide

- Prevents machinery and equipment from overheating, reducing failures

- Prevents mold and bacterial growth, maintaining hygiene standards

- Creates more comfortable environments for human and product movement in logistics operations

A well-designed ventilation system directly increases warehouse efficiency, as it ensures employee safety and preserves the quality of stored products. Air circulation is vital especially in warehouses storing food, pharmaceuticals, and chemicals. For this reason, ventilation systems should be prioritized in every warehouse plan.

The Impact of Air Circulation on Preserving Product Quality

One of the factors that directly affects product quality in warehouse environments is air circulation. In areas where products with high sensitivity to temperature and humidity are stored, stagnant air can, over time, lead to undesirable chemical reactions, odor formation, and surface deformation. In environments without regular airflow, shelf life is reduced, packaging can be damaged, and the reliability of the product delivered to the customer may be questioned.

A well-planned air circulation system balances temperature and humidity indoors, protecting the physical structure of products. For example, humidity imbalance in textiles can damage fabric texture, while heat build-up in electronics can negatively affect the performance of circuit components. At the same time, proper airflow optimizes air exchange between products, preventing mold, fungi, and bacteria growth. This offers a significant quality advantage, especially for sensitive sectors such as food and pharmaceuticals.

Air circulation is not only a climate-control element but also a quality-control tool that preserves the freshness and structural integrity of products. When a healthy air cycle is not ensured at every stage of storage, losses in product quality cause financial damage and undermine brand reputation. Therefore, any business that aims to sustain product quality should treat in-warehouse air management as a priority investment item.

The Use of Helicopter Fans in Warehouses and Logistics Centers

Using helicopter fans in warehouses and logistics centers is a powerful solution for effective air circulation across large volumes. In high-ceiling buildings, warm air accumulates above while cool air remains below. Helicopter fans balance these different temperature layers and make the ambient temperature uniform. This balance both increases employee comfort and boosts the efficiency of heating and cooling systems.

Helicopter fans can provide high airflow at low speed over a much wider area compared to conventional fan systems. This feature prevents dust from remaining suspended in warehouses with heavy forklift traffic, creating a healthier working environment. At the same time, they help maintain humidity balance and prevent issues such as condensation on racks. These fans direct airflow in large areas in a controlled manner without disrupting warehouse operations.

Helicopter fans also stand out in terms of energy efficiency. Affecting more area with less energy, these systems reduce operating costs in the long term. They offer a sustainable choice for businesses that want to both save energy and improve indoor air quality. Contributing to performance, health, and product quality in logistics centers, helicopter fans are an important component of modern warehouse management.

Which Factors Affect Airflow in Warehouse Design?

The factors that affect airflow in warehouse design are not limited to the location of ventilation systems. From the physical structure of the building to the interior layout, many details determine how efficiently air will circulate. In particular, high rack systems, narrow aisles, the number of entry-exit doors, and the placement of fans directly shape airflow. When these elements are not planned correctly, air becomes stagnant in certain areas, which both disrupts thermal balance and complicates humidity control.

Main factors affecting airflow in warehouse design:

- Ceiling height of the building and overall architectural structure

- Placement of rack systems and aisle widths

- Type, number, and positioning of fans

- Orientation, frequency, and open duration of entry and exit doors

- Physical nature of stored products and their arrangement

- Location of walls, columns, and other physical obstacles

- Placement of natural ventilation openings and windows

Optimizing airflow is important not only for comfort or energy savings, but also for protecting product quality and employee health. Evaluating these factors holistically during the warehouse design process directly affects the business’s long-term efficiency. Every correct choice made at the planning stage prevents future issues such as moisture problems, temperature imbalances, or stagnant air.

Common Problems Related to Air Circulation

Common problems related to air circulation in warehouses and logistics areas often arise from infrastructural shortcomings that are not immediately apparent but can lead to serious consequences. Especially in large, high-ceiling facilities, non-uniform airflow results in temperature differences, humidity imbalances, and stagnant air zones. This both makes it difficult to store products under healthy conditions and negatively affects employee comfort and work efficiency.

Major common air-circulation problems:

- Stagnant areas caused by lack of airflow in certain zones

- Build-up of harmful gases indoors due to insufficient air exchange

- Hot and cold pockets caused by imbalanced heat distribution

- Condensation, mold, and rust arising from moisture accumulation

- Incorrect fan placement or low-capacity ventilation systems

- Performance loss over time due to lack of maintenance

- Storage layouts planned in ways that obstruct airflow

If such problems are not prevented, not only physical product losses but also health and safety risks can emerge. Poorly planned air circulation leads to increased operating costs and operational disruptions. Therefore, from warehouse design to maintenance processes, air circulation should be prioritized at every stage and supported with regular inspections.

Leave a Comment